What are the main causes of wind turbine fires?

The two main causes of wind turbine fires are lightning strikes and mechanical failure. Although, there are other potential causes too, such as electrical malfunction and human error during maintenance.

Why are wind turbine fires so destructive?

Wind turbine fires are so destructive because the materials that a wind turbine is made from can be highly flammable. Most fires also originate in the nacelle which contains many flammable substances and is located very high up on the turbine, well beyond the reach of firefighting crews. Over 90% of wind turbine fires result in complete or highly significant loss.

Does Drax Technology's system integrate with my existing fire panels?

Yes, our system integrates with, and is able to interlink, fire panels from over 50 fire alarm manufacturers.

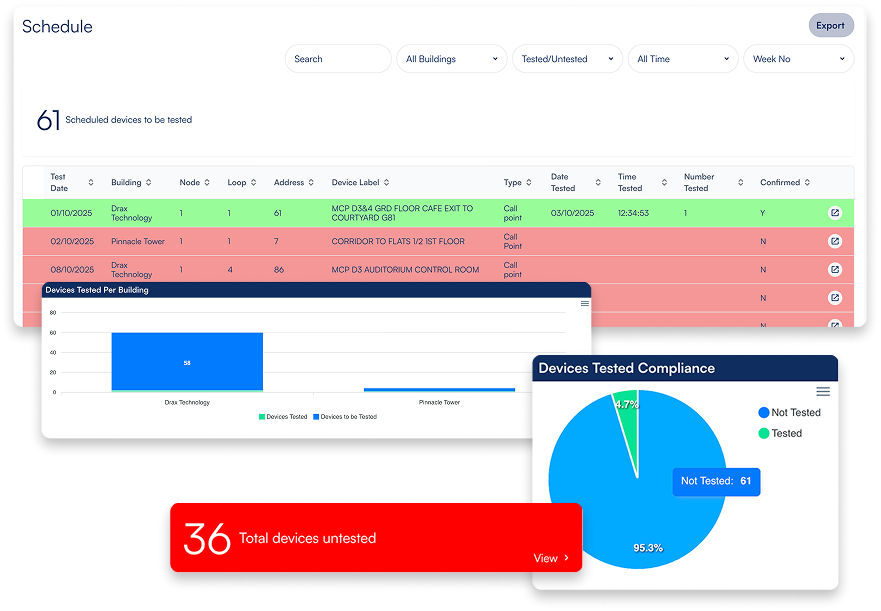

How does Drax Technology help with wind farm compliance?

Our system helps with wind farm fire compliance by automatically recording an audit trail of all fire events across all fire safety assets within a portfolio. It also has a dedicated compliance hub for easy compliance reporting.

What is critical alarm management in a wind farm context?

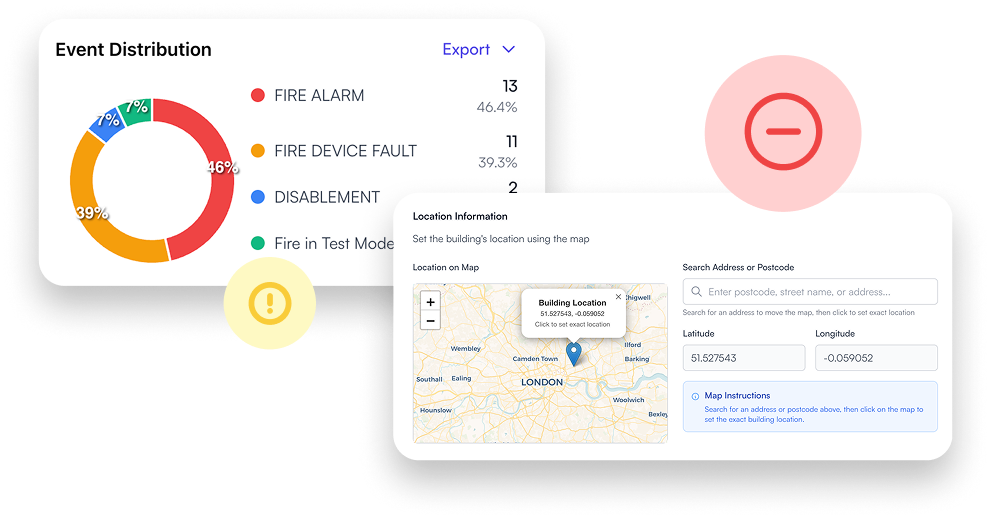

Critical alarm management in a wind farm context is using a centralised platform to monitor and manage all fire safety assets on each wind turbine in real-time. The insights this provides can result in fewer false alarms, early detection of potential fire risks, and shortened emergency response times.